- 回首頁

- 機械工業雜誌

- 歷史雜誌

摘要:中空鍛造製程即使用水平多軸複動化鍛造成形模組,鍛製出具有中空孔之無毛邊鍛品,達到精密、省料及省機械加工之目的,其製程主要用於銅質多軸中空孔管件接頭之產品,具有極大之經濟效益。然而水平多軸複動化鍛造模組結構複雜,設計不易,該技術在業界並不廣泛。本文以衛浴用四通銅質管件接頭為載具,進行水平分割多軸複動化模組技術之探討與研究。首先收集國內外文獻,加以分析複動化鍛造模組與成形機構設計,結合連桿機構與油壓式閉模鍛造機構,開發水平複動化鍛造模組;並使用DEFORM模擬軟體分析成形中材料流動之情形,設計具四軸之水平複動化鍛造模組。最後進行C2680黃銅材料之熱間鍛造實驗,探討模組之可行性。結果顯示,經DEFORM模擬分析顯示四軸向水平複動化鍛造成形為可行方式,本文所開發之水平複動化模組可成功地將目標載具鍛造成形,且鍛件之流線顯示均勻無切斷,尺寸合格。在鍛造實驗中,合模力約為150噸,鍛造成形所需之負荷約300噸,模組運作順暢,顯示本文之空心鍛造製程與水平多軸複動化鍛造成形模組為可行。此一四軸向水平複動化鍛造成形方式,所需材料為1.51 kg,比較傳統有毛邊方式之下料重為2.36 kg,可節省約0.85 kg材料重,約為原下料的36%。

Abstract:The objective for making precision forgings and for saving the usage of materials can be reached by using multi-action forging die set to do the core forging process. But the horizontal multi-ram and multi-action forging die set is complex and difficult to design. The processes are primarily applied to the manufacturing of multi-axis cored joint parts. In this article, the brass joint which has four axes is used as the vehicle to investigate the die set of horizontal split and horizontal multi-action forging die set. First, the information of developed multi-action forging die set will be collected and be analyses. Then, the die set is designed and developed by combining a link mechanism and a hydraulic clamping mechanism. At the same time, the forging simulation software DEFORM is used to analyze the stress and strain in the die as well as the situation of material flow during forging. The optimum conditions of the process will be investigated and established by the simulation results. According to the optimum conditions, the horizontal multi-action forging die set with four rams will be tried. Finally, the feasibility of the die set is investigated by hot forging of forging brass C2680. The results showed that the horizontal multi-action forging with four rams is feasible through the simulation of DEFORM. The design of the horizontal multi-action forging die set in this article is feasible as well. The target vehicles are forged successfully by the developed die set and the flow lines of the forgings are reasonable. The dimensions are conforming to the requirements of the drawings. In the actual forging experiment, the clamping force is set at 150 ton and the total forging load is around 300 ton. At the same time, the movement of the die set is smoothly. Therefore, the development of the core forging process and the die set is successfully. Comparing with the traditional flash forging, the horizontal multi-action forging can reduced the materials from 2.36 kg to 1.51 kg. The materials of 0.85 kg can be saved, which is around 36% of the materials in the flash forging process.

關鍵詞:水平多軸、複動化鍛造、管件接頭

Keywords:Horizontal multi-ram, Multi-action forging, Brass joint

前言

由於全球在鍛造技術上均朝向尺寸精密化,下料省料化及生產快速化三個方向來發展。而為達到此目標,亟需開發精密複動化鍛造技術,才能鍛製精密無毛邊之鍛件,除此之外,由於工程減少,製程易於自動化亦可節省人力[1]。

傳統的鍛造方法大都應用於鍛製實體鍛件,但是若像高壓管件、歧狀閥件等具有單方向或多方向中空孔穴之特點,若以傳統鍛造成形之方式鍛製,必須加上鍛製前所需之加熱及鍛製後之剪緣、鑽孔等機械加工,則整個元件所需之製程可能多達十數個道次。此時,若應用複動化鍛造成形模具進行複動化鍛造,即可達減少道次、材料、時間之目的[2]。複動化鍛造製程主要是以擠壓為主,同時結合了閉模鍛造的複合成形技術,把多個工程道次結合起來用一組模組或設備進行鍛造成形[3]。

所謂複動化鍛造即表示沖頭與模具間是可相互運動,此有別於傳統一體型模具,傳統鍛造法之模具結構係為一體型模具,在模具上有拔模角與毛邊之設計,鍛造完成後尚須將鍛件剪緣去除毛邊,故造成下料時材料之浪費及後續機械加工量增加;而複動化模組與沖頭為分割並可相互運動,基本上成形之過程為上、下模具先行合模後,左右沖頭或上、下沖頭再擠入模穴,將材料擠壓成形充填模穴,模具與沖頭為複動。由於複動化鍛造的鍛胚是經過精密計算,胚料體積需控制在1%以內,所以相對的在整個鍛造過程中合模力(clamping force)需足夠閉鎖,以避免在成形過程中上、下模被撐開而有毛邊產生,若是胚料體積過多則因為胚料在密閉模穴中成形,會造成模具因成形時所產生的內應力過大,使模具造成應力破壞,降低模具壽命。而沖頭之動作是藉由機構之設計將垂直方向的成形力轉換為上下前後左右三方向力量。如此,便可得到無毛邊之鍛件,甚至可成形具有側向中空孔之鍛件[4-6]。

水平多軸複動化鍛造技術開發

1.水平多軸複動鍛造模擬分析應用

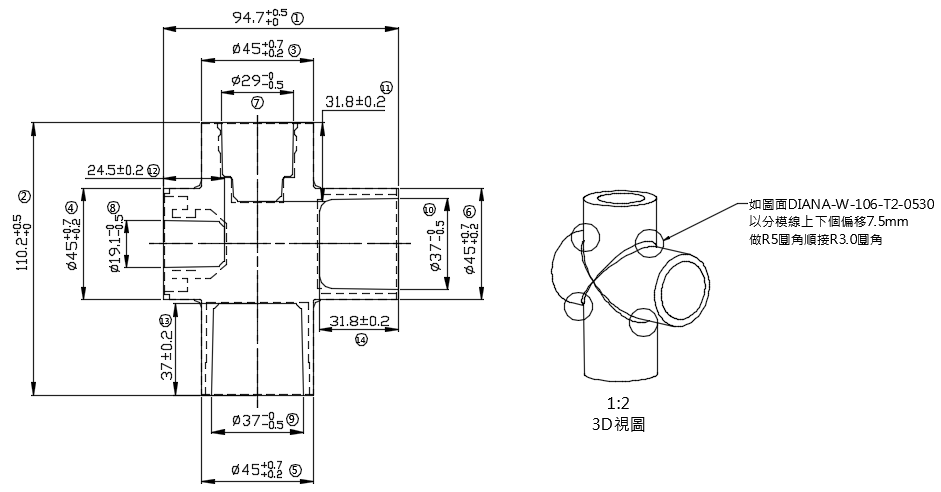

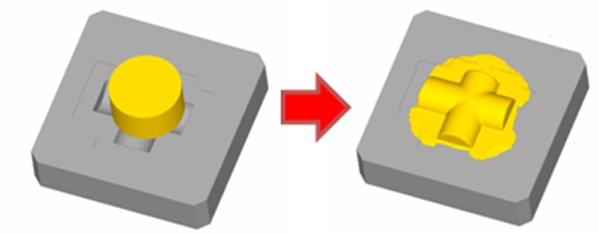

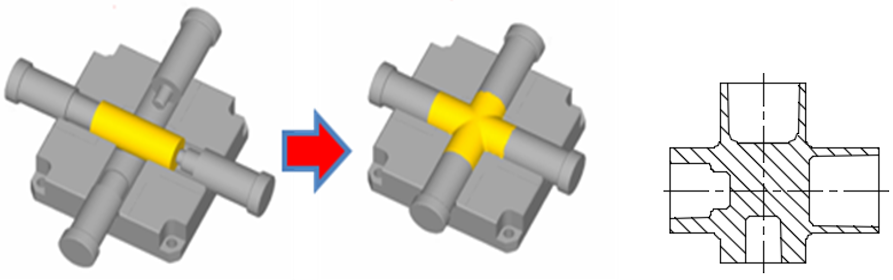

以衛浴用四通管件接頭為載具,開發其空心鍛造製程與水平多軸複動化鍛造成形模組。載具如圖1所示。傳統鍛造製程是以有毛邊之鍛造方式進行鍛造作業,下料重量為2.36 kg。由於四通管件接頭最終成品為軸部有中空孔穴之設計,鍛後去除毛邊,須進行機械加工,如圖2所示。若能採用水平複動化鍛造方式鍛製,以一次完成鍛製作業,鍛件無毛邊,並完成部分軸部中空孔,則可節省材料,減少機械加工量與加工時間,可降低生產成本,如圖3所示。此水平複動化鍛造之鍛胚設計,下料重量約為1.51 kg,預估可節省約0.85 kg左右。因此,此一四通管件接頭之空心鍛造製程與水平多軸複動化鍛造成形模組值得投入開發。

圖1四通管件接頭之機加工圖面

圖2 傳統有毛邊鍛造方式,下料約2.36 kg

圖3 水平複動化鍛造方式與空心鍛胚設計,下料約1.51 kg

回文章內容列表更完整的內容歡迎訂購 2022年12月號 (單篇費用:參考材化所定價)